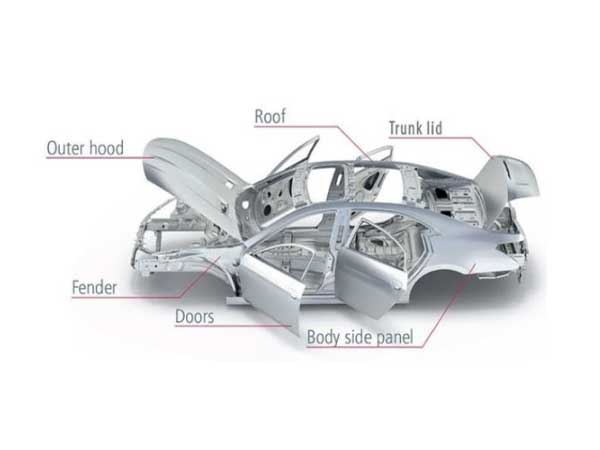

BIW = Automobile body shell/structure are welded together Structure before painting called BIW

| UnitTitle | Title |

|---|---|

| Body type | 1) Monocoque 2) Body on frame |

| Material used in BIW | 1) Steel 2) Aluminum 3) Carbon fiber reinforce plastic |

| Design consideration | 1) Aerodynamic & good appealing shape of overall BIW structure 2) BIW must be corrosion resistant & law weight 3) Sufficient space for occupant/load caring capacity 4) Overall structure stiffness & strength should be good enough to perform On road testing parameters. |